Cellulose packaging made using compostable raw materials; substrate and inks.

The cellulose film, metallised with enhanced barrier properties, was printed with water-based inks from the FlexiBio series, certified compostable, and using Carbon Neutral-certified.

The cellulose film substrate is a material derived from renewable raw materials, with heat-sealable properties, characterised by barrier properties against moisture, gases and aromas, and resistance to oils and fats.

The printing plates used to print the cellulose are Carbon Neutral certified and made by Asahi Kasei using AWP™-DEW water-based technology, which has a lower environmental impact.

Cellulose packaging has the environmental advantage of lowering the carbon footprint of the printing process compared to conventionally produced packaging, i.e. using traditional film/plastic substrates, alcohol-based inks and photopolymer plates washed with solvent.

The use of Carbon Neutral certified inks and photopolymer plates in the production of our packaging allowed us to reduce the carbon footprint of our packaging in relation to conventional packaging by 12%.

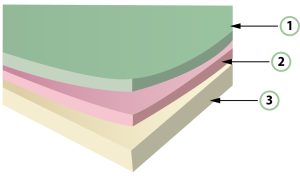

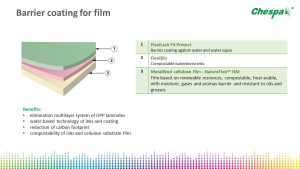

Packaging scheme /beginning with outer shell/:

- FlexiLack FX Protect – barrier coating against water and water vapor

- FlexiBio – compostable waterborne inks

- Metalised film based on renewable resources, compostable, heat-seable, with moisture, gases and aromas barrier and resistant to oils and greases

Benefits of packaging:

- elimination multilayer system of OPP laminates

- water-based technology of inks and coating

- reducing the negative impact on the environment

- compostability of inks and cellulose substrate film

- the use of water-washable photopolymer plates, which are certified Carbon Neutral

- waste management and disposal in countries with low waste recycling rates.

In order to analyse a broader spectrum of the environmental impact of our packaging, the study was extended to include the extent of the toxicological impact on humans and the environment. The study shows that cellulose packaging made from compostable certified raw materials reduces toxicity in comparison to packaging made from conventional raw materials by 11% in terms of human toxicity, 93% in terms of ecotoxicity, 25% in terms of marine ecotoxicity and 45% in terms of freshwater ectoxicity.

Thanks to the raw materials used in the manufacture of the chocolate packaging, we have not only managed to reduce the carbon footprint of the packaging, but have also made a significant contribution to reducing toxicity to the environment, mainly the hydrosphere and the organisms living in it. The reduction in the greenhouse gas CO₂ as well as the reduction in the environmental impact of toxicity, eutrophication and ozone depletion mean that chocolate packaging has a lower environmental impact. In addition, the use of compostable cellulose-based substrates, both industrially and domestically, opens up the discussion on waste management in areas of the world where waste management in the form of re-use – recycling – is almost non-existent. We feel that compostable packaging is an ideal solution for waste management and disposal in African countries, where recycling processes are at a lower level than in EU countries. The average recycling rate in EU countries is at 32.5 %¹, while only 4 %² of waste is recycled on the African continent.